New machine, spare part, or service support—pick the right option and we’ll get back to you fast.

Your solution is just a click away!

Get in touch to find the perfect machine for your business.

Get the right parts, fast and hassle-free.

Keep your machines running at peak performance—contact us today.

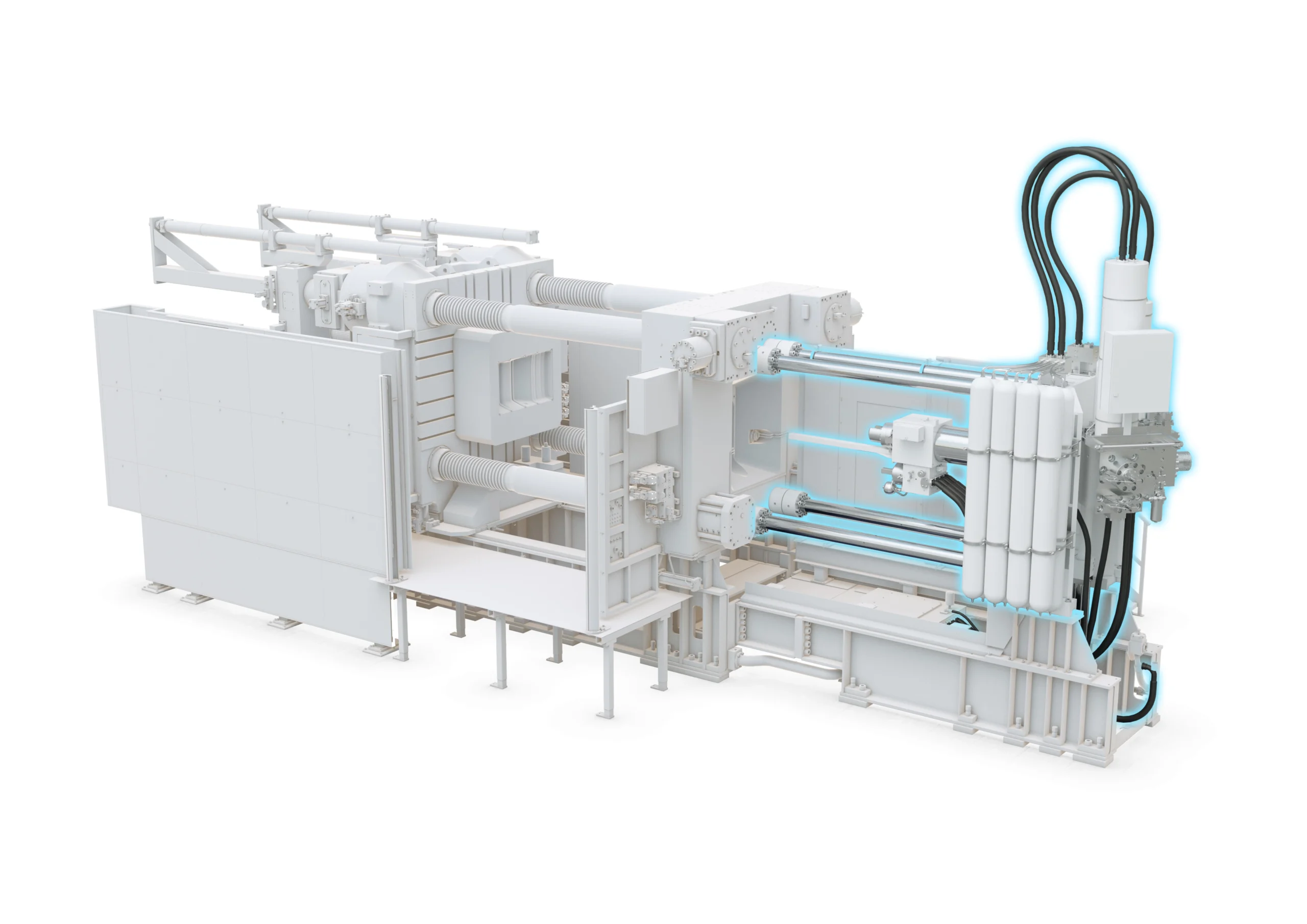

The new range of digitally enabled TF machines, previewed at this year’s EUROGUSS, will be modular by design, meaning they can be more easily configured to meet the exact requirements of each individual customer and easily readapted should casting needs change.

In fact, over 55 different configurations will be possible. With closing forces ranging from 1,400 to 11,000 tonnes, 6 types of injection, and at least 2 closing unit options for every machine size, foundries will always be able to specify their perfect match.

As well as offering greater flexibility and, thanks to the giant closing forces available, the ability to cost-effectively cast bigger structural components in larger quantities, these next-gen machines have significant cost and futureproofing implications for customers.

Their modular configuration means we can ship the pre-tested, pre-certified modules quicker, at less cost, and assemble on location ensuring faster delivery and ‘right-first-time’ performance. All concepts we have tested in real life. What’s more, if casting needs change, so can the configuration of the machine readapting it with a new module. It’s Simple. That’s why we call it SmartPlatform.

The new TF models, available as individual machines or supplied as part of a fully automated cell, are also designed for sustainable productivity. An absolute essential when more and more end-customers are making environmental performance part of contract scope.

Lighter in weight and featuring ECO Fit as standard means TF technology use less energy to build and operate. In fact, over the course of 10 years the carbon emissions saved is equivalent to taking 961 flights around the world.

Meanwhile, features familiar on the long time established ItalPresseGauss TF technology all combine to deliver consistent high-quality castings and super low scrap rates.

The hardest certified alloy steel platens in the industry, well equalized tie bar loads, a hydraulic locking system able to compensate for any geometrical imperfections of the die or thermal expansions, and a SC.4 shot end system with real time injection control, work in harmony to guarantee casting repeatability while also minimizing aluminium waste.

All machines come installed with Norigate, gateway technology that collects, timestamps, and encrypts data from any machine it is connected to before sending it to the cloud. Together with ItalpresseGauss’ Monitizer solutions suite this unlocks a range of process optimizing capabilities to help die casters drive down scrap rates and energy consumption, and drive up profitability.

Mario added: “The launch of our leaner, greener, next generation of TF machines means we are going to be able to deliver best in class parts and solutions in less time, helping customers to increase productive time and to adapt quickly to changing requirements.

With many die casters diversifying or having to adapt parts and processes to meet new end-customer demands – especially linked to light-weighting and sustainability – this delivers a huge Value.”

Our team is ready to guide you through our latest models and help you find the ideal solution for your production needs. Fill out the form and let’s start the conversation.

Contact us via form below, email info@italpressegauss.com or phone +39 030 9749300.

Quickly and easily order spare parts or accessories for your machines. Complete the form and we’ll make sure you get exactly what you need without delay.

Contact us via form below, email parts@italpressegauss.com or phone +39 030 9749500.

Schedule maintenance or service requests with our experienced team. Fill out the form, and we’ll take care of the rest, ensuring your operations stay smooth and efficient.

Contact us via form below, email service@italpressegauss.com or phone +39 030 9749500.