New machine, spare part, or service support—pick the right option and we’ll get back to you fast.

Your solution is just a click away!

Get in touch to find the perfect machine for your business.

Get the right parts, fast and hassle-free.

Keep your machines running at peak performance—contact us today.

It all began with a rethink of how space is used at a Siemens AG location in Germany. The die casting operations at the company’s Bad Neustadt facility was going to have to ‘move house’. The project team was given a new building to redesign the die casting of components for Siemens electric motors from scratch.

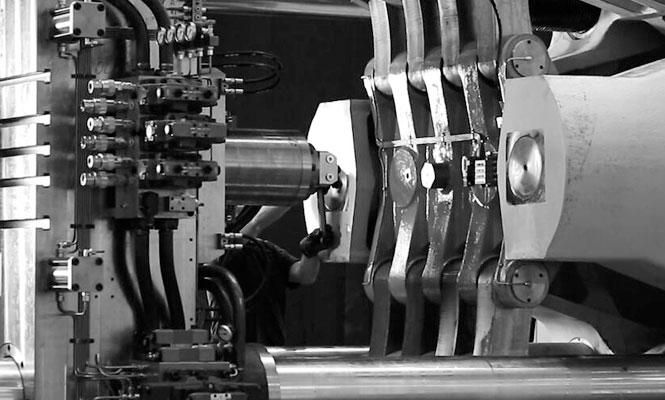

Two new, fully automated die casting cells were to become the heart of the new facility. The existing tools quickly narrowed down the choice to a three-platen cold-chamber machine. Beyond this machine type, the team had a raft of specific requirements for the new cells.

“We very much wanted a complete solution, an all-inclusive package. At the same time we had some pretty exacting specifications for the equipment manufacturer: for example, we wanted the robot, trimming press and furnace from specific brands. That alone requires additional integration efforts that not every supplier is willing or able to make. On top of this, the new solution had to be compatible with our own IIoT operating system MindSphere and would, wherever possible, use Siemens components – electric motors, for example.”

Volker Ress, who led the project at Siemens in Bad Neustadt

The team chose two die casting machines from ItalPresseGauss, types IP 750 SC and IP 550, with a closing force of 750 and 550 tonnes respectively. They were delivered on schedule in autumn 2018 as turn-key, fully automated cells, including robot, feed device, sprayer, immersion cooling basin, trimming press and dosing furnace. Both cells were started up within only a few weeks and have been running in three-shift operation ever since.

For the team at Siemens, the engineering and integration of such a cell, and defining all its interfaces, was a task for experts: focus during the purchasing process was very much on ensuring any potential partner had the ability to deliver a complete solution. One that works, seamlessly, even when integrating special requests and specifications.

Ultimately, we want a solution that is ready to go and a folder that tells us everything we need to know to run it. The team at ItalPresseGauss have been incredibly flexible and have realised and integrated all our special requirements without any problems.

Volker Ress, Siemens

The ability to connect to MindSphere was particularly important to Siemens. Machine controls have to be primed for new demands in terms of data collection – by offering sufficient internal memory, for example – and have to be open for local IIoT integration.

Volker Ress explains: “Openness, both technical and organisational, is key. The equipment manufacturer has to be happy for us to plug an ethernet cable into the machine and grab data straight from the PLC. I need a system that gives me data relevant to the die casting process. ItalPresseGauss’ HMe machine control does just that.”

“Flexibility in the specification of die casting cells is becoming more and more important. Aluminium foundries have their individual, specific requirements and are increasingly asked to integrate these cells into sophisticated production systems. In this context, Industry 4.0 is only one aspect – albeit an important one. For us, all of this is simply an exciting challenge. The more open we are to unusual customer requests, the more technologies and components we get to see and know. It allows us to constantly expand our knowledge and find the best solutions for our customers faster. A big thank you to the Siemens team for setting us such an interesting task!”

Marco Giegold summarised the project for ItalPresseGauss

Our team is ready to guide you through our latest models and help you find the ideal solution for your production needs. Fill out the form and let’s start the conversation.

Contact us via form below, email info@italpressegauss.com or phone +39 030 9749300.

Quickly and easily order spare parts or accessories for your machines. Complete the form and we’ll make sure you get exactly what you need without delay.

Contact us via form below, email parts@italpressegauss.com or phone +39 030 9749500.

Schedule maintenance or service requests with our experienced team. Fill out the form, and we’ll take care of the rest, ensuring your operations stay smooth and efficient.

Contact us via form below, email service@italpressegauss.com or phone +39 030 9749500.