New machine, spare part, or service support—pick the right option and we’ll get back to you fast.

Your solution is just a click away!

Get in touch to find the perfect machine for your business.

Get the right parts, fast and hassle-free.

Keep your machines running at peak performance—contact us today.

Light metal die casting refers to the production of well-defined aluminium, magnesium, or zinc parts by filling mould cavities with hot, liquid metal which is then cooled to form the desired shape. The moulds used in this process are referred to as ‘dies’ – giving the process its name.

There are three different types of die casting, each with distinct benefits.

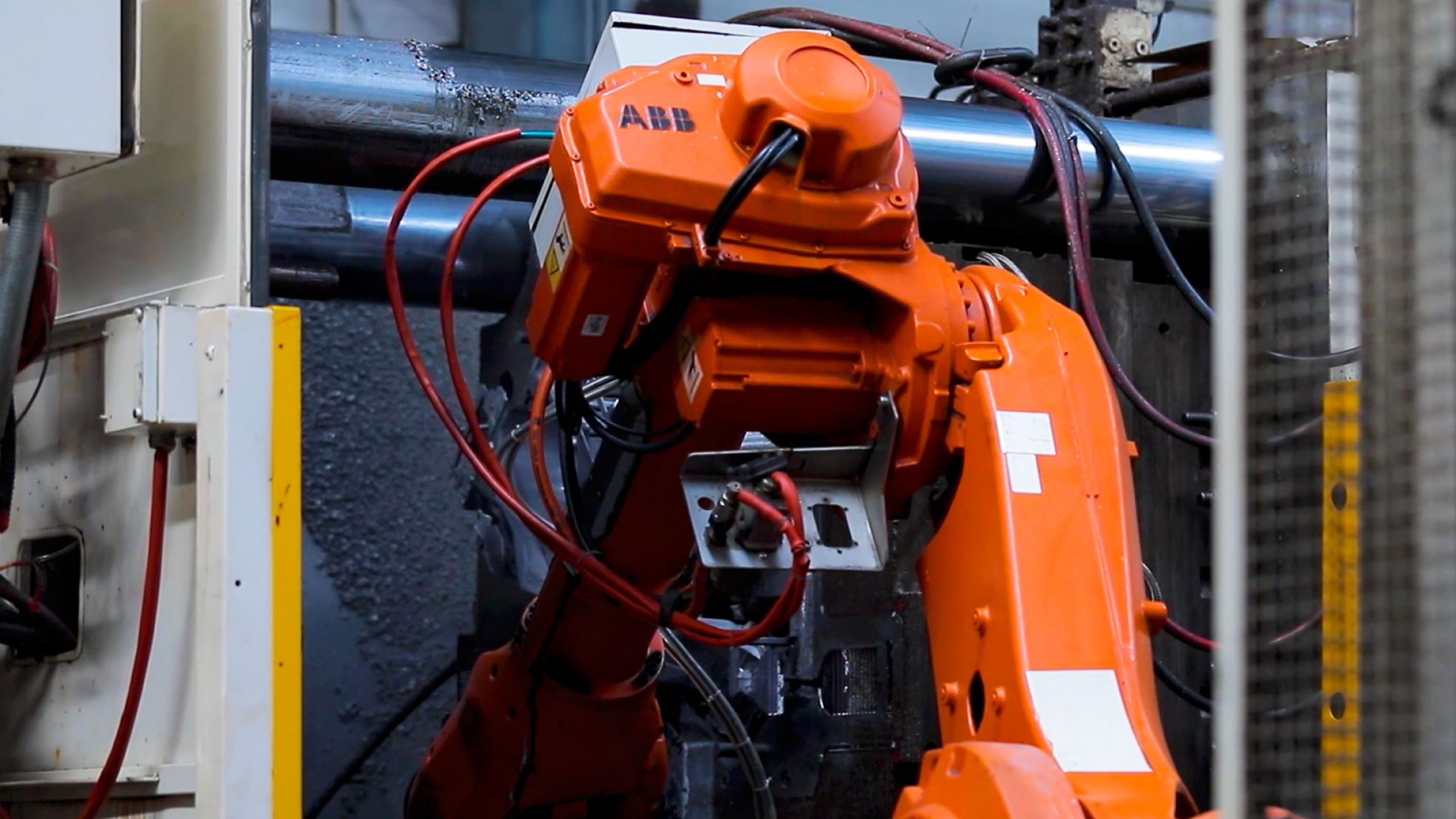

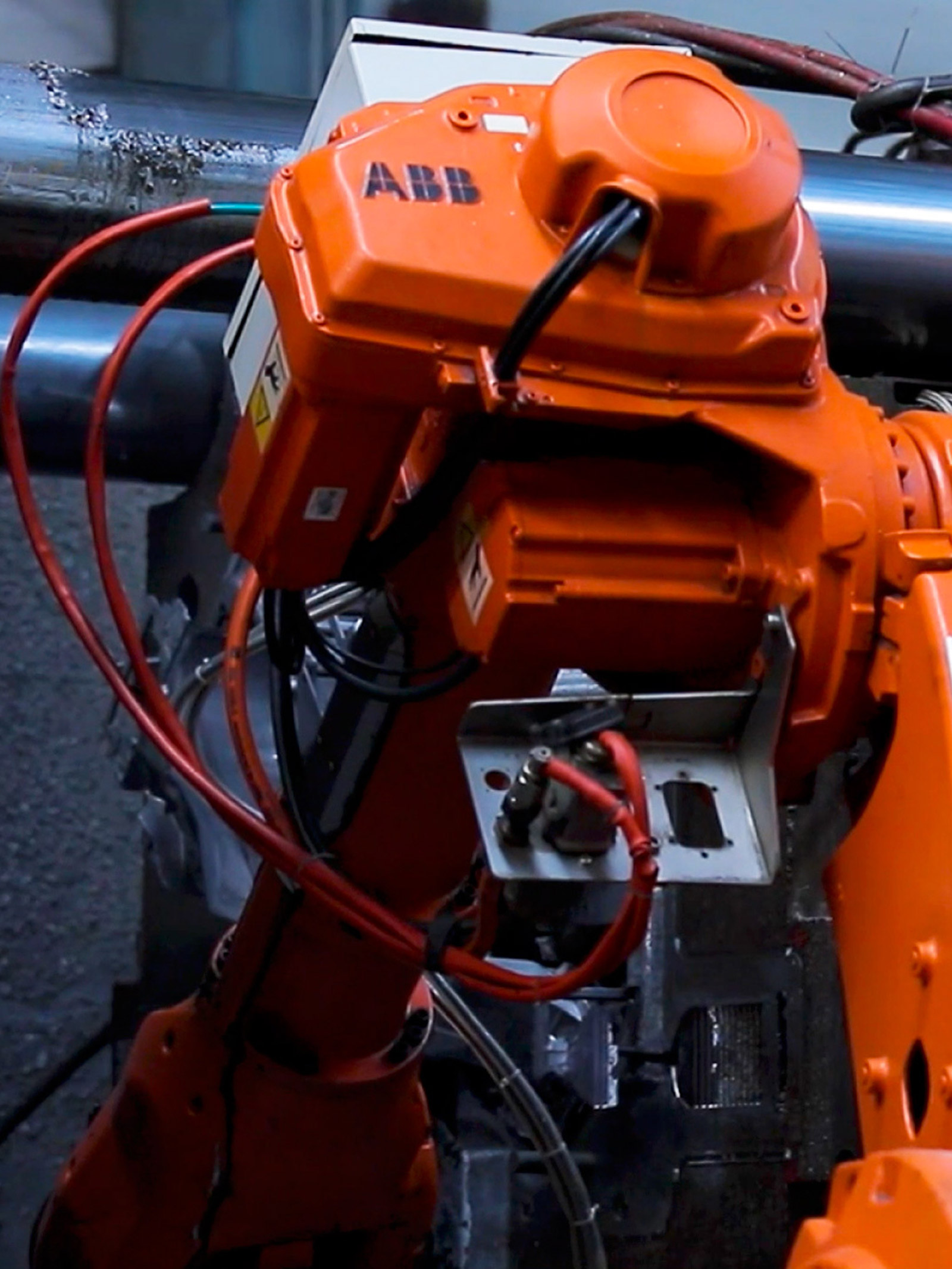

This is when molten metal is forced at high speed and high pressure into the cavity of a closed die. The die is locked tightly in place by powerful closing forces applied by the horizontal HPDC machine used. Once the metal has solidified, the die is released, and the casting is ejected.

This process is best for producing large light alloy parts, in high volumes, at great speed. Castings with excellent surface finish, uniformity and mechanical properties can be achieved.

With gravity die casting, molten metal is poured into a pre-heated semi-permanent/permanent die from a ladle or transfer vessel. The force of gravity fills the die with minimum turbulence through one or more channels to reduce oxidation and foaming.

This process is highly suited to automation and the productivity gains that come with that. It produces dense castings with fine grain structure and strong mechanical attributes.

With a longer cycle time than HPDC, Low pressure die casting (LPDC) machines employ vertical platen closure. Molten metal is injected up into the die cavity by applying pressure to a holding furnace positioned beneath the fixed platen. Pressure is maintained to the closed platens until the metal solidifies.

This process is best for controlled die filling for smaller, intricate parts – especially those with hollow sections or complex geometries. Typically used for shorter production runs.

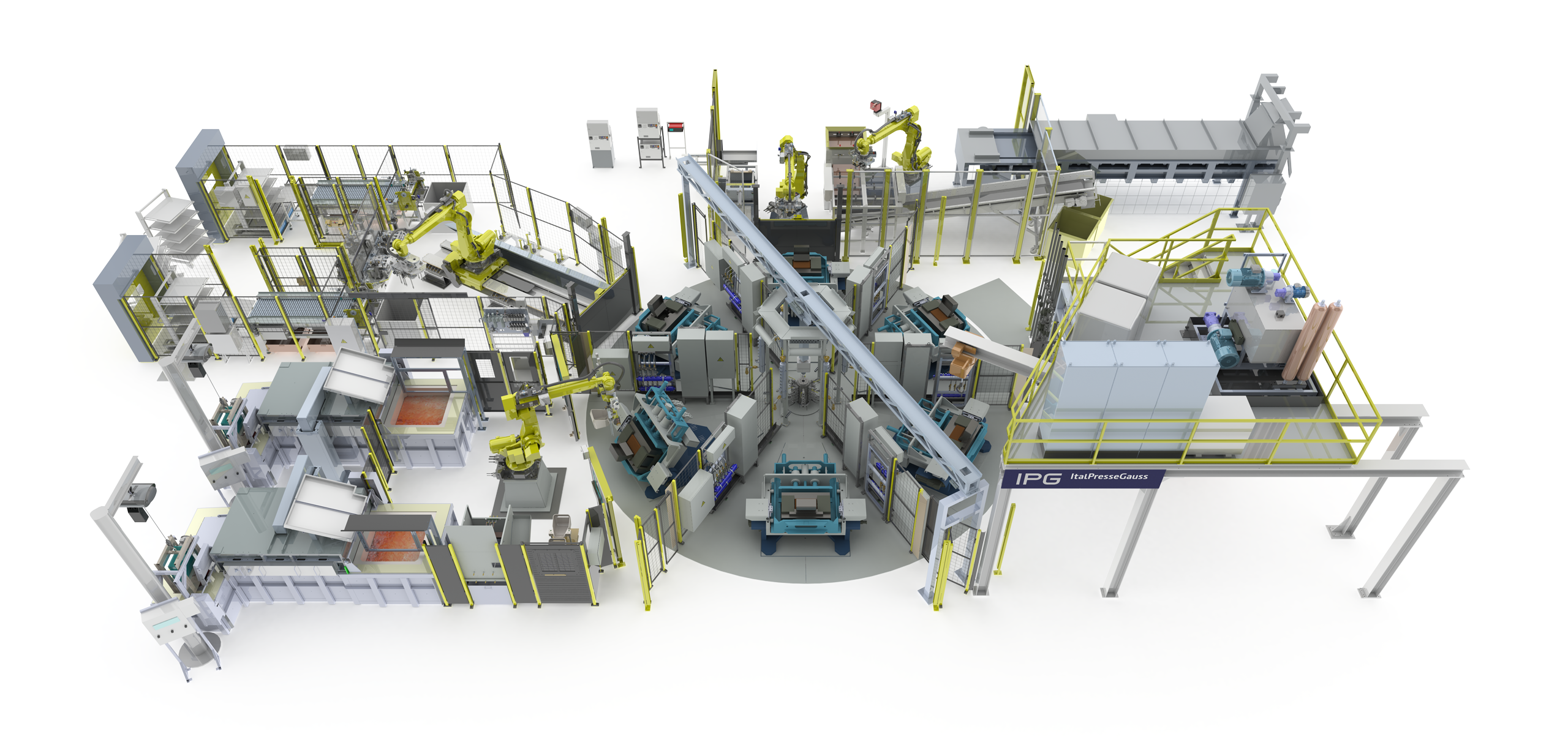

Specialised in light alloy casting, we engineer custom die casting systems and automation to support quality, efficiency and innovation worldwide

We comply with internationally recognised certifications and codes, embedding accountability and ethical best practice across all levels of our organisation

A wide range of applications demonstrates the versatility of our die casting systems, adopted in fields that demand precision, efficiency, and sustainability

Our team is ready to guide you through our latest models and help you find the ideal solution for your production needs. Fill out the form and let’s start the conversation.

Contact us via form below, email info@italpressegauss.com or phone +39 030 9749300.

Quickly and easily order spare parts or accessories for your machines. Complete the form and we’ll make sure you get exactly what you need without delay.

Contact us via form below, email parts@italpressegauss.com or phone +39 030 9749500.

Schedule maintenance or service requests with our experienced team. Fill out the form, and we’ll take care of the rest, ensuring your operations stay smooth and efficient.

Contact us via form below, email service@italpressegauss.com or phone +39 030 9749500.