New machine, spare part, or service support—pick the right option and we’ll get back to you fast.

Your solution is just a click away!

Get in touch to find the perfect machine for your business.

Get the right parts, fast and hassle-free.

Keep your machines running at peak performance—contact us today.

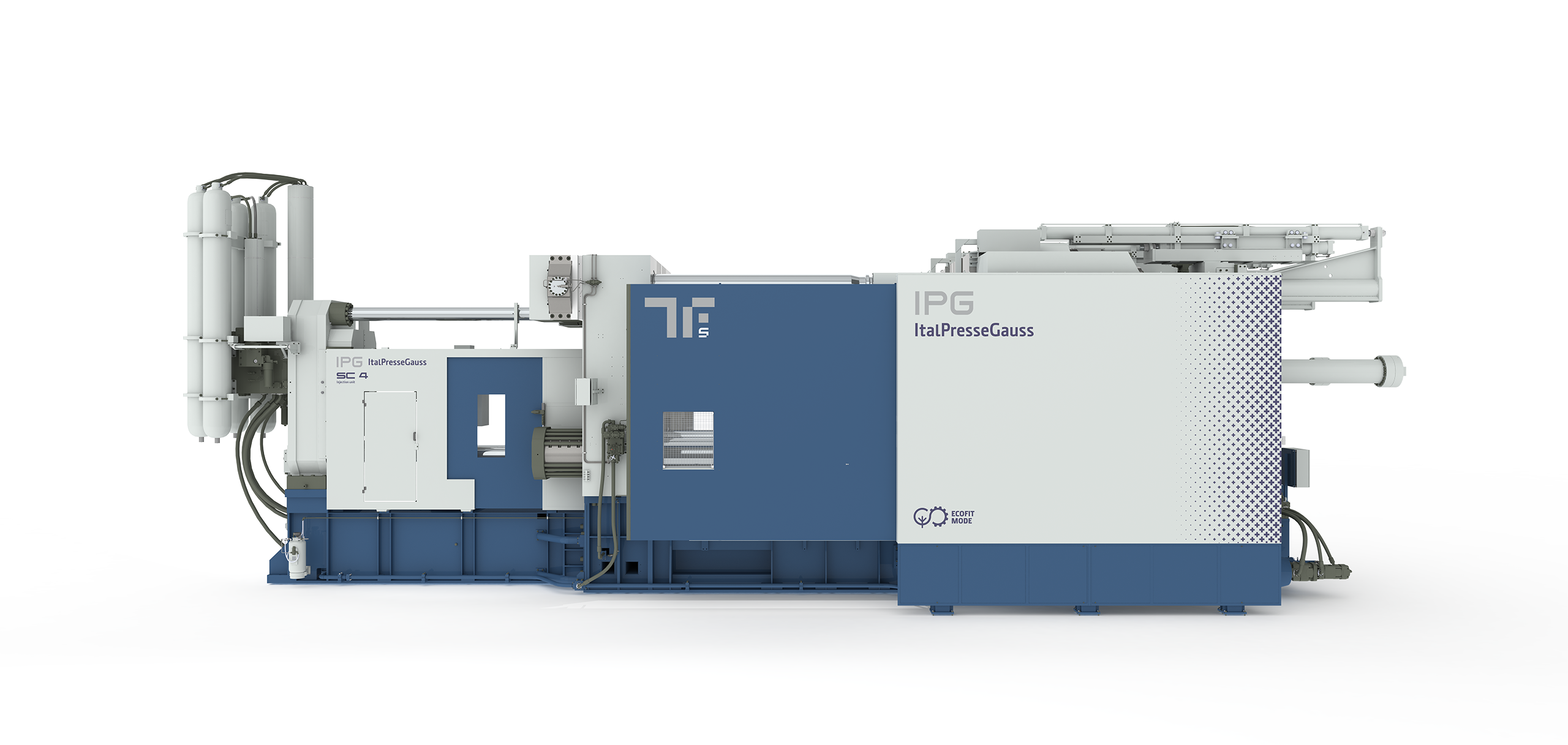

Suitable for producing castings of any size, our powerful TFs machines optimize every aspect of casting, from minimizing maintenance and space requirements to improving shot accuracy and die closure. If you want consistent high-quality casting, these machines make it simple.

With up to 6 different injection options (ranging in speed, force, and stroke) and closing forces from 1400t to 11000t, we’ll configure the perfect TFs machine for your specific needs. And if those need change, we can easily reconfigure machine modules – futureproofing your investment.

Lighter, durable components mean your machine will consume less energy and last longer, while also minimizing maintenance and downtime. All packed into a smaller footprint.

The rigidly constructed closing unit, well equalized tie bar loads, powerful closing forces, and a hydraulic locking system able to compensate for die imperfections and thermal expansions, mean you get rock-steady production, minimised die distortion and super low scrap rates.

The SC.4 shot end system with injection control reacts to real-time melt flow data, adjusting the speed of the piston to guarantee uniform casting quality. The system also minimizes maintenance requirements for increased machine uptime.

Our TFs machines are lighter to build and operate, saving energy and helping to reduce carbon emissions. They also come with ECOFIT as standard, saving even more energy during production cycles.

Our machines are ideal for a diverse complex casting production and when the die is frequently changed. Some applications include:

structural parts (battery housing, car roof, shot tower, pillars), engine blocks, gearboxes, oil sumps, engine suppor

5G, radiators for household heating, escalator steps, chassis and components for electronic devices, telecommunication components, household appliances, electric motors

You might also be interested in

Our team is ready to guide you through our latest models and help you find the ideal solution for your production needs. Fill out the form and let’s start the conversation.

Contact us via form below, email info@italpressegauss.com or phone +39 030 9749300.

Quickly and easily order spare parts or accessories for your machines. Complete the form and we’ll make sure you get exactly what you need without delay.

Contact us via form below, email parts@italpressegauss.com or phone +39 030 9749500.

Schedule maintenance or service requests with our experienced team. Fill out the form, and we’ll take care of the rest, ensuring your operations stay smooth and efficient.

Contact us via form below, email service@italpressegauss.com or phone +39 030 9749500.