New machine, spare part, or service support—pick the right option and we’ll get back to you fast.

Your solution is just a click away!

Get in touch to find the perfect machine for your business.

Get the right parts, fast and hassle-free.

Keep your machines running at peak performance—contact us today.

For users of gravity die casting equipment, this means reduced manual intervention of operators during the core setting phase as well as less need for auxiliary equipment such as supports.

Previously, an operator would position the core manually on a dedicated support, paying particular attention to the correct positioning of the core. With the new system, cores no longer need dedicated supports that would have to be built or bought especially. This, and the reduction of manual intervention, translates into cost and time savings in the production cycle.

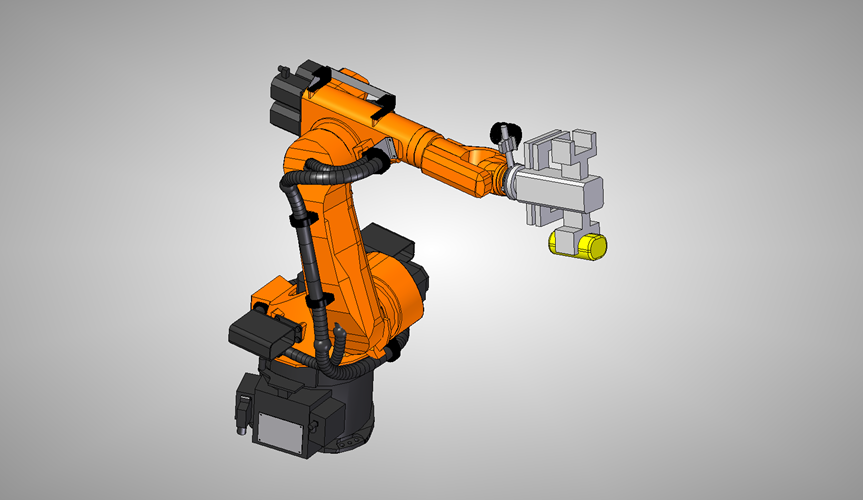

Through a 3D scan, the system detects the type, position and orientation of the cores on the tray. The information is given to the robot that automatically orientates the gripper to pick the next core.

Where different castings are produced, and consequently different cores are needed, the system is able to recognise the right type of core and introduce it correctly into the production cycle.

During the core picking phase, the system also checks the integrity of the core. If it is intact, the core is passed on and positioned for the core setting operation; if it is defective, the robot automatically ejects the core from the production cycle and transports it to a waste unloading area.

The solution is part of ItalPresseGauss’s Industry 4.0 efforts, providing cutting-edge systems ready for integration – to meet the needs of customers who are looking to use digital technology well to maintain their competitive edge.

Our team is ready to guide you through our latest models and help you find the ideal solution for your production needs. Fill out the form and let’s start the conversation.

Contact us via form below, email info@italpressegauss.com or phone +39 030 9749300.

Quickly and easily order spare parts or accessories for your machines. Complete the form and we’ll make sure you get exactly what you need without delay.

Contact us via form below, email parts@italpressegauss.com or phone +39 030 9749500.

Schedule maintenance or service requests with our experienced team. Fill out the form, and we’ll take care of the rest, ensuring your operations stay smooth and efficient.

Contact us via form below, email service@italpressegauss.com or phone +39 030 9749500.